Links:

In summary, window and door fittings are an essential aspect of home design that should not be overlooked. They contribute to the aesthetics, security, energy efficiency, functionality, and maintenance of our living spaces. Whether you are renovating your home or building a new one, it’s crucial to invest in high-quality window and door fittings that meet your personal style and practical needs. By doing so, you can create a safe, comfortable, and beautiful home that stands the test of time.

Aluminum louver profiles for windows

Cast Iron Panels for Sale – A Modern Twist on a Classic Material

Aluminium profiles have emerged as a leading choice in the construction of window frames, thanks to their excellent durability, design flexibility, and thermal efficiency. The use of aluminium profiles for windows not only enhances aesthetics but also optimizes energy performance, making them a popular option for both residential and commercial applications.

The side-hung design is popular with traditional or modern homes. Here, the window hinges from the top and bottom, with the window handle on the side.

In conclusion, window aluminium profiles have revolutionized the way we perceive and construct windows. Their durability, energy efficiency, aesthetic appeal, and eco-friendliness make them a preferred choice in modern architectural design. Whether it's a contemporary high-rise or a heritage restoration project, aluminium profiles offer a solution that is both practical and aesthetically pleasing, enhancing the functionality and beauty of any structure. One of the main reasons ornamental iron castings are so widely used is their durability. Iron is a strong and long-lasting material that can withstand harsh weather conditions and heavy use. This makes it ideal for outdoor applications, such as gates and fences, where it will be exposed to the elements. Ornamental iron castings can also be easily maintained with regular cleaning and maintenance, ensuring that they will last for many years to come.Also known as Hardcoat, it is relatively thick and denser than both chromic and sulfuric acid anodize.

Our Advantages:

With the wheels loose, gently lift the door slightly off the track so that you can access the wheel assembly Maintenance is another crucial factor when considering any type of fencing, and wrought iron fence panels are relatively low maintenance compared to other materials. While they may require occasional cleaning and painting to prevent rusting, the sturdy construction means that they are less likely to suffer from damage caused by weather or wear and tear. Moreover, aluminium glazing beads offer exceptional versatility. They can be customised to match various architectural styles, thanks to their ability to be powder-coated in a wide range of colours. This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance

This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance aluminium glazing bead. In conclusion, ornamental iron castings are a timeless and versatile choice for adding beauty and elegance to any design. With their durability, aesthetic appeal, and sustainability, these castings are a popular option for a wide range of applications. Whether used in a grand architectural feature or a simple decorative accent, ornamental iron castings are sure to make a lasting impression. In conclusion, if you are in search of wrought iron supply near me, there are plenty of options available to meet your needs. Whether you prefer to shop in person at a local store or online from the comfort of your home, you can find the perfect wrought iron materials for your next project. With its timeless beauty and exceptional durability, wrought iron is sure to add a touch of elegance to any home or garden. The history of ornamental iron posts dates back to the Industrial Revolution when the mass production of iron made it more accessible and affordable. Skilled blacksmiths transformed this robust material into intricate designs, each piece reflecting a unique blend of strength and beauty. Today, these posts continue to captivate with their timeless appeal, whether adorning a grand mansion or a modest suburban home.

aluminium glazing bead. In conclusion, ornamental iron castings are a timeless and versatile choice for adding beauty and elegance to any design. With their durability, aesthetic appeal, and sustainability, these castings are a popular option for a wide range of applications. Whether used in a grand architectural feature or a simple decorative accent, ornamental iron castings are sure to make a lasting impression. In conclusion, if you are in search of wrought iron supply near me, there are plenty of options available to meet your needs. Whether you prefer to shop in person at a local store or online from the comfort of your home, you can find the perfect wrought iron materials for your next project. With its timeless beauty and exceptional durability, wrought iron is sure to add a touch of elegance to any home or garden. The history of ornamental iron posts dates back to the Industrial Revolution when the mass production of iron made it more accessible and affordable. Skilled blacksmiths transformed this robust material into intricate designs, each piece reflecting a unique blend of strength and beauty. Today, these posts continue to captivate with their timeless appeal, whether adorning a grand mansion or a modest suburban home. Why Is Aluminum Best For Windows And Door Profiles?

Slimline Aluminium Profile A Versatile Solution for Modern Design

The door and window handle, therefore, are not just functional accessories but also subtle expressions of design language. They narrate a story, setting the tone for the space they inhabit. They are the punctuation marks in the architectural narrative, silently yet significantly contributing to the overall ambiance and user experience. In today's fast-paced world, security has become a top priority for both residential and commercial properties. One effective way to enhance the safety of your home or business is by installing metal pull-down security doors. These doors offer numerous benefits that make them an excellent investment for anyone looking to protect their property.

WHAT ARE THE TYPES OF ALUMINIUM WINDOWS?

Moreover, aluminium glazing beads offer exceptional versatility. They can be customised to match various architectural styles, thanks to their ability to be powder-coated in a wide range of colours. This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance

This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance This allows them to blend seamlessly with the overall design of the building, adding a touch of sophistication and elegance aluminium glazing bead.

aluminium glazing bead.  They come in various lengths and styles, allowing for customization and personalization of the fence design They come in various lengths and styles, allowing for customization and personalization of the fence design

They come in various lengths and styles, allowing for customization and personalization of the fence design They come in various lengths and styles, allowing for customization and personalization of the fence design wrought iron fence parts catalog. Whether you opt for a simple straight rail or a more intricate design with decorative elements, rails play a crucial role in the overall look and functionality of a wrought iron fence. One of the most appealing aspects of stainless steel boxes with locks is their versatility. From household storage to industrial applications, they find a place in various domains. In homes, they can be used to store important documents, jewelry, or even as a stylish container for pantry items. In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage

wrought iron fence parts catalog. Whether you opt for a simple straight rail or a more intricate design with decorative elements, rails play a crucial role in the overall look and functionality of a wrought iron fence. One of the most appealing aspects of stainless steel boxes with locks is their versatility. From household storage to industrial applications, they find a place in various domains. In homes, they can be used to store important documents, jewelry, or even as a stylish container for pantry items. In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage

In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage In industries, they serve as secure toolboxes, protecting tools and equipment from theft and damage stainless steel box with lock. They are also widely utilized in the marine industry due to their water-resistant properties.

stainless steel box with lock. They are also widely utilized in the marine industry due to their water-resistant properties. Beyond their practical benefits, wrought iron rail parts also offer a classic and elegant look that can enhance the overall design of a space. The intricate designs and decorative elements found in wrought iron railings add a touch of sophistication and charm, making them a popular choice for both traditional and contemporary architecture. Whether used in a grand staircase, a balcony railing, or a garden fence, wrought iron rail parts can elevate the aesthetic appeal of any setting.

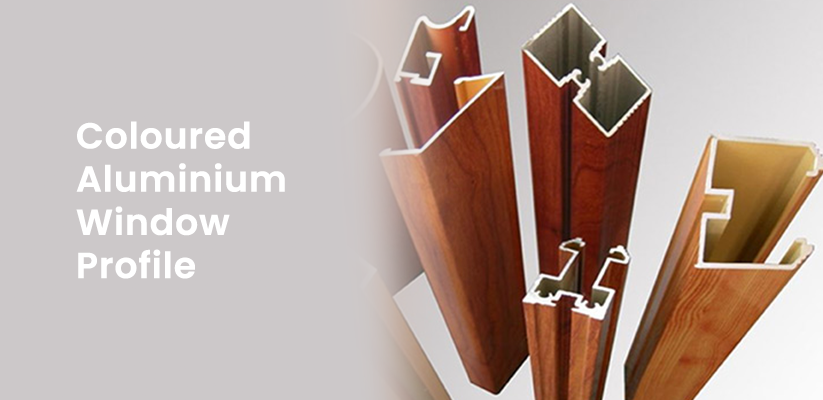

Silver, champagne, Bronze, Golden, Black, White, Gray, Sand coating, Anodized Acid, Alkali, and wood texture, or Customized

Despite their many advantages, wrought iron fence panels do require some maintenance to keep them looking their best. Regular cleaning and painting can help prevent rust and maintain the appearance of the panels. Additionally, any damage should be repaired promptly to ensure the longevity of the fence. When it comes to the design of a main gate steel gate handle, it is not just about functionality; it's also an embodiment of style and security. The main gate, being the first point of contact for any visitor, sets the tone for the entire property. Thus, the steel gate handle design plays a crucial role in creating a lasting impression.The Debate of Doors vs

. Wheels A Look into the Numbers and ImplicationsThe main differences between cast iron and wrought iron are their physical properties and manufacturing processes. Wrought iron is manufactured through heating, bending, and working, while cast iron products are released into their appropriate shapes. It is nearly universally agreed that cast iron is more accessible to produce than wrought iron.

However, wrought iron is more substantial than cast iron, so it is more likely to be used in commercial applications. Conversely, cast iron is harder than wrought iron and can resist deformation under pressure or stress more quickly than wrought iron.

On the other hand, iron is a pure metal that is much softer and more ductile than steel. While iron is still a strong material, it is not as strong as steel due to its lack of carbon content. Iron is also more prone to rust and corrosion, which can weaken its structural integrity over time.

steel or iron stronger

As the movable part of windows and doors, hardware accessories must guarantee the performance and quality to ensure the safety of windows during long-term using time. Windows and doors handle need to conform to ergonomic design, high transmission performance, wear resistance and corrosion resistance; hinges require high hardness, strong toughness and not easy to deform; locks require smooth opening and closing and tightly engaged.

Common surface treatment processes for aluminum doors and windows are electrophoretic coating, fluorocarbon spraying, wood grain transfer coating, anodizing, and electrostatic powder coating. In most cases, after good surface treatment, aluminum profiles have good atmospheric corrosion resistance. It is moisture-proof, sunscreen, flame proof, aging proof, high-temperature deformation proof, low-temperature embrittlement proof, durable and stable, and suitable for various climates.

Pros

Cast iron ornamental fencing became popular in the early 1900’s due to the cost efficiency of manufacturing the different components of ornamental fencing. Cast iron utilizes molds for the different parts. Steel is melted to extreme temperatures and poured into molds. Once cooled the parts are separated from the molds, cleaned of burns and excess edges and ready for painting. There are several large manufacturers who supply primarily welding sloops who produce the bulk of cast iron ornamental fencing in today’s market.

In a nutshell, the main difference between these two types of surface finish is the oxide layer. Anodized finish has a layer of oxide, whereas mill finish does not have the oxide layer.

Easy Maintenance

Another advantage of ball bearing sliding door rollers is their ease of installation. These rollers are designed to be easily mounted onto the door frame, making it a simple process for homeowners or contractors to replace old or worn-out rollers. With just a few tools and some basic DIY skills, anyone can install new ball bearing rollers and restore smooth operation to their sliding doors.